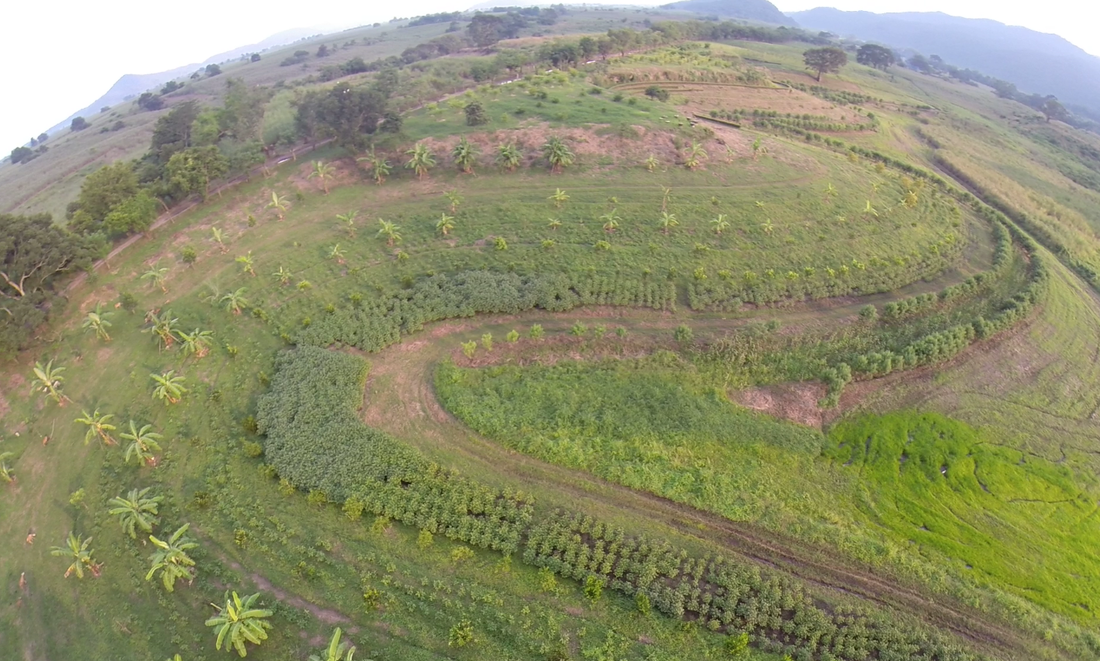

low cost resilient Farm Scale Permaculture design; working with what you've got... Rancho San Ricardo, Veracruz, Mexico Rancho San Ricardo, Veracruz, Mexico This is a brief reflection on our recent trip to Veracruz, Mexico. We went over to run a 10 day Regenerative Ag workshop at the incredible Rancho San Ricardo in tandem with working on design for the 134 Ha ranch Granja Nut, both of which are connected to La Margarita Sugar Mill which services approximately 110,000 Ha of plantation. With the future of the sugar industry in uncertainty and with regional soils & waters in bad shape, the pioneering owner is molding a vision to demonstrate diversification that meets local needs in terms of food, fiber and energy in a way that fosters and benefits the multitude of people inherently connected to the mill and the surrounding economies. Slides above from my first visit to the mill, showing the whole process at the other end of your sugar spoon... The initial design work was conducted by MasHumus and Jesus Ruiz, working on installing the initial access and hydrological layers at the San Ricardo site. With the main access running along the main ridge, the primary ridge & valleys formations make for a highly visual demonstration of Keyline Design. Thanks to Pablo & Tere's efforts (along with the team at the farm) the site is really coming along, with a lot more planting, maturing and introduction of animals since I first visited. Sugarcane is still produced on the ranch and will obviously be highly important for the wider area until the industry declines. However, one of the objectives of this project is to start meeting more needs locally whilst restoring the carbon and hydrological cycles. Somehow the future feels closer here, a little raw and a little exposed. There is a long dry season that stalls the sub tropical growth, so effective management of soil and water resources is vital. The evidence of past abuse is close to hand. There is pedestalling of over 600mm at the base of the tree you see in both pictures below, at the southern end of the San Ricardo site. Intensive plow agriculture takes its toll even faster in these climes, probably the majority of this was lost in 40- 50 yrs; the result of plowing up and down hills and exposing bare soil to tropical rains.

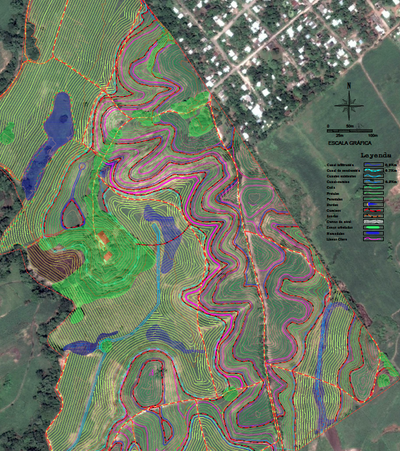

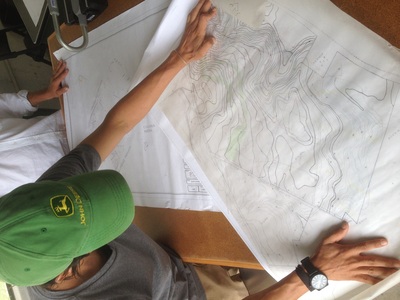

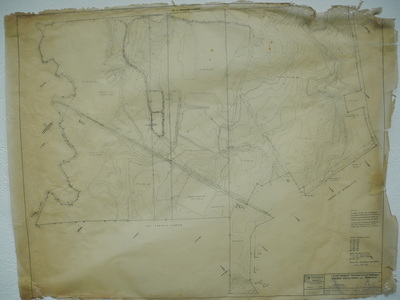

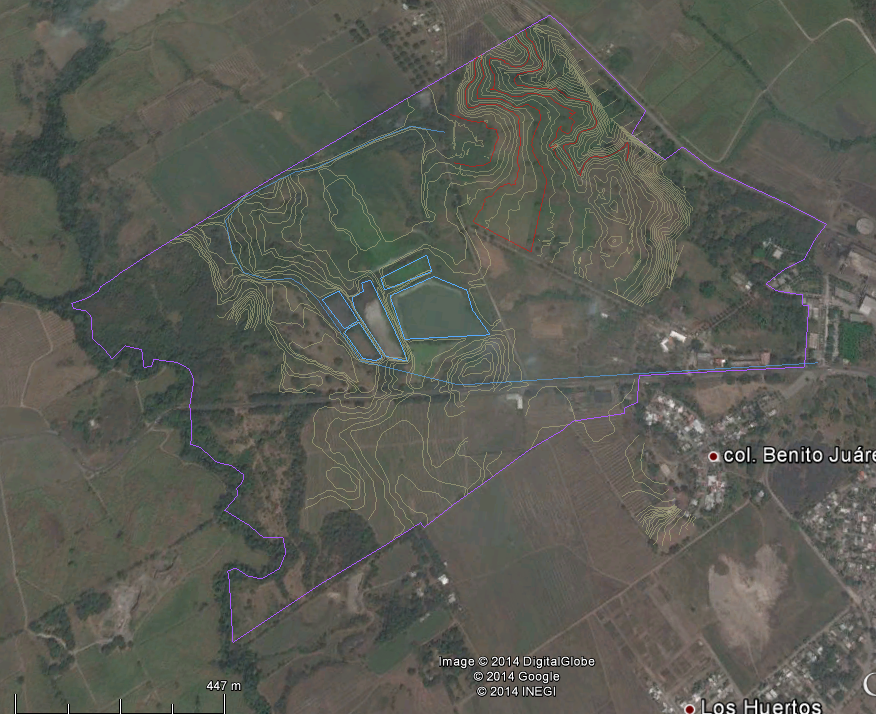

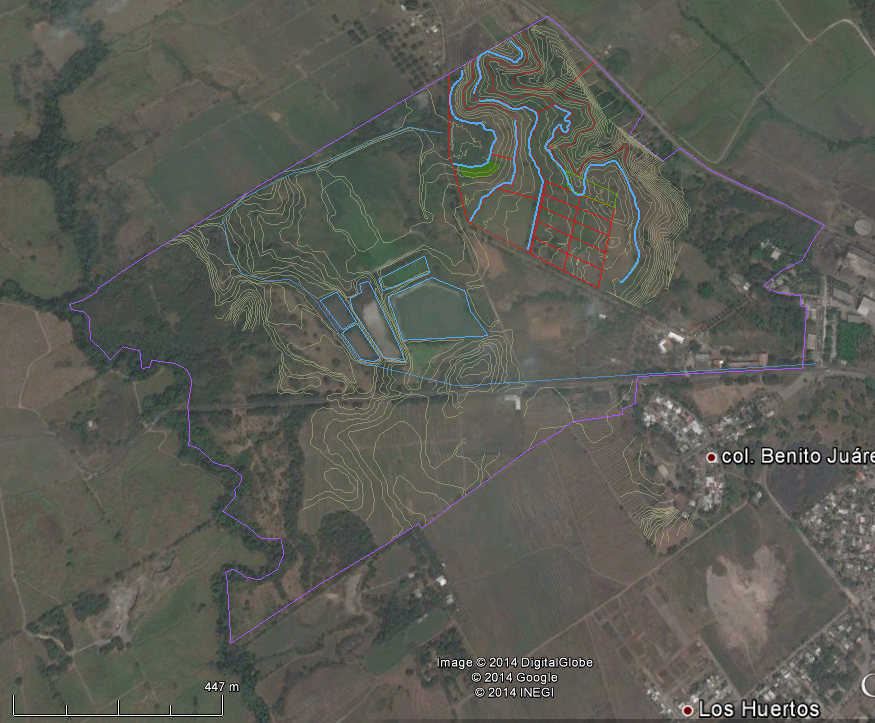

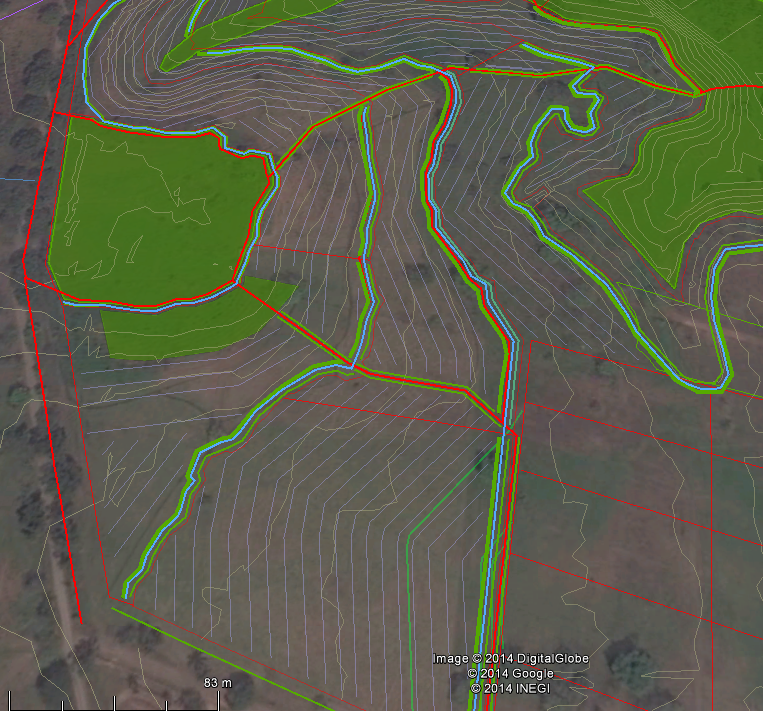

Two of my past students, Rodrigo & Antoninio live and work at the site, both having taken part in a PDC, and Rodrigo in a Dryland Water Management & 10 Week Farm Scale Permaculture Internship; so we have a solid platform & connection for coherent design work together. Rodrigo is passionate about Holistic Management and is dealing with the dairy herd whilst Antoninio works with the Tree Nursery and educational outreach. They;re both doing great work. When I first arrived and looked for mapping we heard there were quotes for $10K for 50cm topo's for the farm. One of our aims was to develop a highly affordable, highly practical & productive approach to taking the farm into a more resilient and diversified future. After some gleaning of the resources on site we found an old 50cm topo from the 1980's for part of the ranch (where the lagoons lie) and I decided to combine this with another digital map of the pastures which I could reference with other mappage lying around and digitize the whole thing. An evenings work later (overlaying maps and tracing topography) and we now have a 50cm topo map of the whole farm. Perfect! Unusually the paddocks are divided up by permanent fencing running on contour around the ranch. This might have been done because contour ditches have been used to utilize some of the mills waste water for irrigation in the dry season. We're not sure. I always like to see if we can work with what we already have. Whilst my mind can quickly jump into "what is the optimal design for this landscape?" cost, practicality & resources (context) need to be carefully factored in. More and more in design work I am asking myself "what don't we need to do here; how simple can we keep it?" I like this approach; we have saved people a bunch of money and possibly unintended consequences when it comes to strategies such as extensive earth-working that may not be necessary or even optimal. Finding opportunties in problems

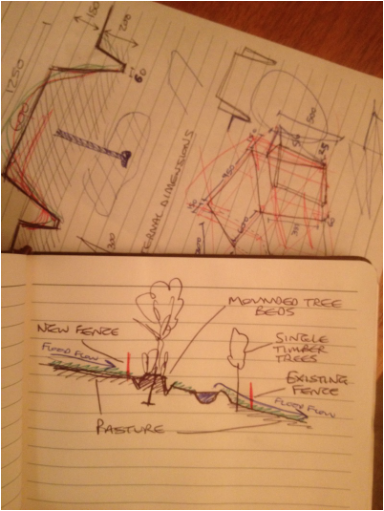

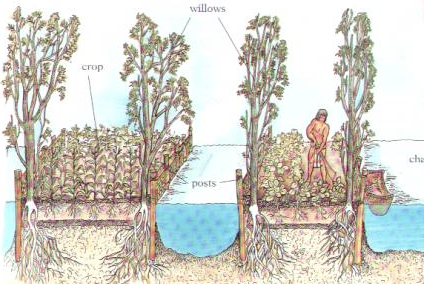

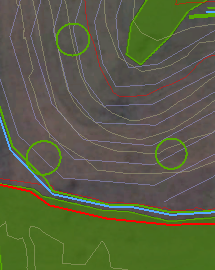

On my first visit I had the great privilege to visit the remaining Chinampas systems in the south of Mexico City, the wondrous remains of what was once arguably the most resilient of farming systems (see slideshow below) Driving around the ranch I began to wonder how we could use the bamboo and timber on site, along with the 40,000 tons of cachasa (pressed cane waste) that comes out of the factory annually to build chinampas that make the water travel through the lagoons in a long slow motion to aid cooling, and find the right plant assemblies to clean some of the organics out at the same time as producing a useful yield of biomass, etc. Wouldn't that be something, so appropriate to the region. John Todd's approach at a Tyson chicken processing plant in Maryland had to deal with over double the volume of water (which I don't think was hot) that contained a lot higher levels of residues and subsequent BOD levels. The way these lagoons are set up gives scope for the system to function totally by gravity with irrigation water being taken from the last pool. The option to divert water around the entire canal system direct onto the pasture (at the highest point) still remains. Obviously there would be some substantial investment, mainly a lot of labour, but I would envisage the cost to be totally appropriate for a serious industrial unit to take full responsibility for a substantial amount of water. Looking forward to future developments on this front! Slides from my visit to the Chinamapas with my wonderful biologist friend Ignacio Working with what you've got Utilizing the water for flood flow irrigation seems totally viable, and has been done with trenches made with a butterfly plow attachment and tractor annually. This seemed to work to some degree, but on inspecting the paddocks I found some of the lines went up and down slope and seemingly had not been surveyed. This will obviously not work optimally, so I began studying the map and looking for options. Wanting to see if we could work around the existing fencing we started sketching out layout ideas. One aspect that played into this was that farm access was poor, in times of wet ground there were numerous dips where even 4x4 vehicles had trouble. I sat down with Rodrigo to start laying out flood flow irrigation ideas, alongside farm access and tree lanes.

Starting to sketch out how to stack functions around what already exists at the ranch... Starting to sketch out how to stack functions around what already exists at the ranch... Talking with Pablo about tree planting at San Ricardo, I learnt that trees had been either planted by hand or with a tractor powered augur. Given the efficacy of our tree planting rig on our farm I started thinking how we could use what was lying around to create a more optimal set up. The problem I could foresee using the augur, besides it being very slow work, was that it could compact up the edges of the hole and create a strange planting hole. I figured if we were going to create permanent flood flow (on contour) then we could use existing fencing to protect it from trampling. Multiple "tiers" of irrigation ditches could be connected by pipe and gate valve down the centre of the ridge that falls from the canal outlet point. In this circumstance dams are just not worthwhile, water is in such great abundance! That means roads, even just graded earthen roads, are simply not an appropriate strategy. Water & unnecessary investment is not needed here in my mind. There is no need for permanent access, but it is always beneficial to delineate vehicle land use patterns to avoid unnecessary compaction on the pasture. We can do that with tree plantings. Starting to sketch ideas I liked the idea of single timber trees on perhaps 4-6m spacings on the downhill side of each berm, protected by the existing fence and still allowing unimpeded flood flow over the berm wall. On the upside of the irrigation ditch I started thinking around the sort of mounded beds we made at Ridgedale on Keyline geometry. As continuous beds these are much quicker to plant, give a much better quality of ground preparation, allow for planting with no tools as well as cover cropping. They would act as a final physical barrier to the flood flow, which should aid vehicle access where that is combined; a pattern that could be repeated across the whole ranch. Paddocks are then individually marked up for Keyline pattern subsoiling and in this case a 10m headland left around any field tree crops for efficient movement of machinery. With year round grass production the only machinery anticipated on the land is tractors pulling subsoilers and mulch mowers, since animal numbers are approximately at 0.5 the potential and there is a clear desire not to bring more large livestock in the foreseeable future. Mulch cutting acts as a fertilizer too, so managing grazing along side this tool can certainly work for now.  Another benefit from having permanent fences running along both sides of the pasture strips is the potential to use a tumble wheel paddock wire for quick and efficient moving of the herd with a single person. Naturally a complimentary egg laying enterprise could benefit & extend this set up reaping benefits for the land as well as bringing another source of income as a by-product of their pasture sanitization services. Some of the existing fencing is not necessarily in the optimal place, eg, if we want to put access down ridge lines, etc, but if tracks are not graded and avenue plantings allow full access then it's not really a big deal. Not really worth the cost of moving any of it at this point. Our goal is how simply, how cheaply, can we add layers of production and ecosystem services whilst optimizing what is already there? Keyline patterned subsoiling and planned grazing regime is already going to have an impact, tree crops will bring all manner of benefits and complimentary enterprises can be added as we go...  During the workshop we looked at different options for mechanizing tree planting and wanting to create solutions at super low cost I remembered the keyline plow they had at San Ricardo which had been modelled for injecting Cachasa into the subsoil. In this region putting organic matter straight onto the ground is somewhat futile (certainly at this scale) It is oxidized so quickly. This machine turned out not so effective. Injected into the subsoil, Cachasa is needed at a rate of 2-3 tons Ha. The mill alone serves 100,000 Ha, the machinery and resources are just not available to make this work at scale. It also seems to only work with a specific moisture content otherwise it clogs, so it's been sat in the barn. I asked the engineers to remove the hopper and leave a single central shanks and see if they could take 2 disks from a cane tiller and mount them on to start experimenting with raised bed creation. Over the next days through various means of translation; people, scribbles, etc, we developed a prototype for deep ripped mounded tree beds to radically speed up and improve tree planting for both the farms. The slides below capture a few of the moments.

Celebrating abundance; farm scale BioFerts, abundant harvests and worm composting. Great work here...

I loved this bamboo bicycle prototype I found at the ranch, pictured below. These folks are certainly creative, and I think this is key to making regenerative enterprises that are good for the land, people and maintain a healthy livelihood. Owning a mill that so many people rely on is a huge responsibility, and I deeply admire the courage and clarity that is driving and pioneering this project. The foundation for everything here is to create nurturing & stimulating livelihoods for all the people here who haven given so much and rely so much on this whole economy. It's off my scale, I guess off most peoples scale, but I admire it wholeheartedly. Antoninio and the Nursery team are churning out thousands of trees of a wide array of great fruit, support & fiber species. With a bit of creative machinery and plants generated on site the overall development can be kept to a very reasonable investment. The benefits will be many. So much great work is happening on the ground here, and it's a real pleasure to engage with dedicated and thoughtful folks to connect dots and see how we can optimally connect and integrate systems to future- proof this incredible place. One aspect of the perennial layer of the design is to plant/ exclude areas of the ranches to create a corridor through the estate to connect primary forest to the west with forest on the NE. Agriculture has taken it's toll and the people here are very aware of that. One of the participants on the workshop is very experienced with endemic ecosystem restoration; presenting her amazing work to the group. It seems like all the necessary resources are falling into place for this ambitious project. What happens here is not limited to the property boundaries by any means. Besides sitting in the heart of over 500,000 Ha of cane production that will inevitably have to shift at some point, I think this place is already one of the prime hubs for Farm Scale regeneration in this part of the world. Its got a bit of everything, and amazing people to boot. This really represents a design sketch; far from a polished master plan with accurate bill of quantities, etc, but what I appreciate about the process so far is the proposition for extremely low cost development leading to long term resilience. The biggest cost in this ranch overhaul would be the addition of the 2nd line of permanent fencing; not a huge cost really. A bit of infrastructure is needed to control the canal flow and allow for distribution (in the way of piping and gate valves) to the various irrigation ditches, which can be installed at low cost. With trees produced abundantly on site, machinery, livestock & tools already existing, much is just about management. I often reflect how the most stable, resilient, low cost & low risk approaches I have been exposed to are based on biological processes, meaning they can be wealth creating. This thought hearkens me back to Allan Savory's words, "you can't solve complex problems with technology." I'm excited to watch the development of this project. HUGE potential and already amazing things accomplished. With my own farm to manage it's becoming less and less possible or desirable to travel far, but this is one place I am excited for our next training event...

3 Comments

23/12/2014 05:25:52 am

What a great and informative article! It is great to see permaculture being applied on such a large scale. Thank you for sharing your work and experiences. I hope you don't mind, but I have shared this article on my blog at oneheartfire.org

Reply

Leave a Reply. |

Details

Like us on FB Below for regular updatesStay up to date with customized updates you want to receive

Upcoming coursesArchives

December 2016

Categories

All

|

RSS Feed

RSS Feed